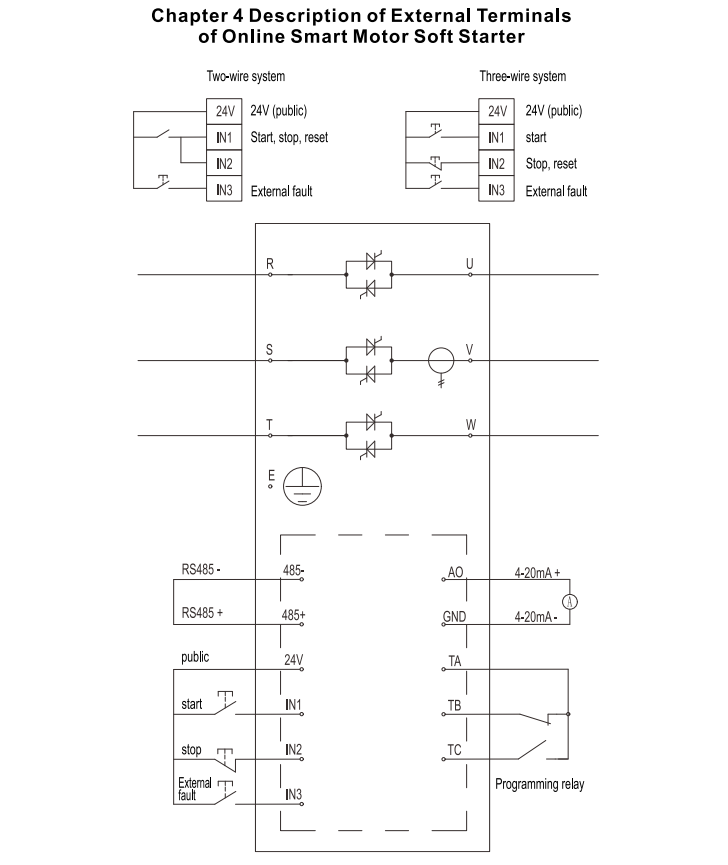

Terminal type | Terminal NO. | Terminal name | Instruction |

Main circuit | R S T | Power input | soft starter 3 phase AC power input |

U V W | soft starter output | connect 3 phase asynchronous motor | |

communication | 485- | RS485- | for Modbus RTU communication |

485+ | 485+ | ||

Digital input | 24V | public | 24V common |

IN1 | start | Short connection with common terminal (24V) Startable soft start | |

IN2 | stop | Disconnect from the common terminal (24V) to stop the start soft start | |

IN3 | External Fault | Short-circuit with the common terminal (24V), soft start and shutdown | |

Analog output | AO | 4-20ma Output Positive | 4-20mA output |

GND | 4-20ma Output Negative | ||

Programming Relay | TA | Programming relay common | Programmable output, available from Choose from the following functions: 0. No action 1. Power-on action 2. Soft start action 3. Bypass action 4. Soft stop action 5. Runtime actions 6. Standby action 7. Failure action |

TB | Programming relay normally closed | ||

TC | Programming relay normally open |

NO. | Fault name | Possible Causes | Suggested solution |

01 | Input phase loss | 1. The start command is issued, and one or more phases of the soft start are not energized. 2. The main board of the circuit board is faulty. | 1. Check whether the main circuit has electricity 2. Check whether the SCR of the input circuit is open, and whether the pulse signal line is in poor contact. 3. Seek help from the manufacturer. |

02 | Output phase loss | 1. Whether the SCR is short-circuited. 2. One or more phases of the motor wire are open. 3. The main board of the circuit board is faulty. | 1. Check whether the SCR is short-circuited. 2. Check whether the motor wire is open. 3. Seek help from the manufacturer. |

03 | Running overload | 1. The load is too heavy. 2. Improper parameter settings. | 1. Replace the soft starter with more power. 2. Adjust the parameters. |

04 | Underload | 1. The load is too small. 2. Improper parameter settings. | 1. Adjust the parameters. |

05 | Soft overheating | 1. The temperature switch is faulty. 2. The fan does not rotate. 3. The working time of soft start is too long. | 1. Check whether the temperature switch is faulty. 2. Check whether the fan is working normally. 3. Stop the machine and let the soft start cool down. |

06 | Over -pressure | 1. The input power supply voltage is too high. 2. Improper parameter settings | 1. Check the power supply voltage. 2. Adjust the parameters. |

07 | Under -voltage | 1. The input power supply voltage is too low. 2. Improper parameter settings. | 1. Check the power supply voltage. 2. Adjust the parameters. |

08 | Running overcurrent | 1. The load is too heavy. 2. Improper parameter settings. | 1. Replace the soft starter with more power. 2. Adjust the parameters. |

09 | Starting overcurrent | 1. The load is too heavy. 2. Improper parameter settings | 1. Replace the soft starter with more power. 2. Adjust the parameters. |

10 | External fault | 1. The external fault terminal has input. | 1. Check whether there is input at the external termina |

11 | Phase sequence failure | 1. The input power phase sequence is inconsistent with the setting. | 1. Adjust the power phase sequence. 2. Adjust the parameters. |